MACHINING CENTERS

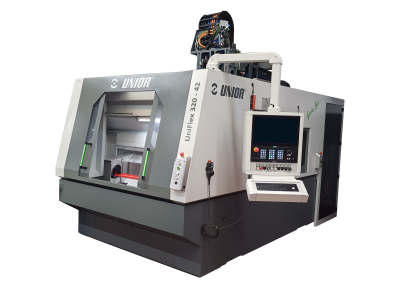

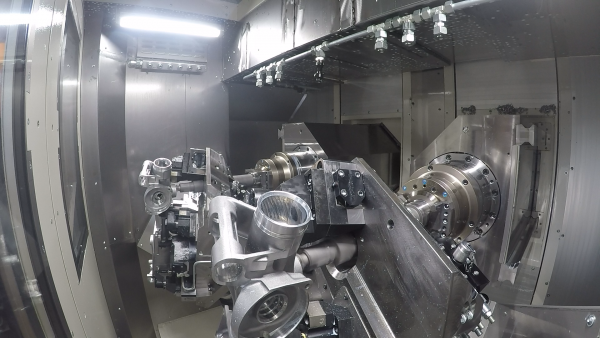

5-AXIS UNIFLEX MACHINING CENTRE UNIFLEX 320-42

UniFlex vertical machining centres are among the best in their class for speed, dynamics, compact design, stability and reliability. Powerful enough for high milling performance, the UniFlex series is available with one, two or four spindles. It is renovned by its 5-axis machining with high productivity, precision, minimal space consumption, simple operation, high stability and easy maintenance.

ADVANTAGES

- Stable and robust construction

- High precision and processing performance

- High machine productivity and lower cost per piece

- Long service life

- 5-axis machining

- 1/2/4 spindle design

TECHNICAL DATA

| Working area | X-Axis | mm | 400 |

| Y-Axis | mm | 430 | |

| Z-Axis | mm | 480 | |

| Spindle | Max. RPM | U/min | 14.000/18.000 |

| Max. power | kW | 15/23 | |

| Distance between spindles | mm | 320 | |

| Tool iterface | HSK | 63 | |

| Acceleration | X-Axis | m/s² | 7 |

| Y-Axis | m/s² | 6 | |

| Z-Axis | m/s² | 8 | |

| Accuracy | Position tolerance | mm | <0,01 |

| Position deviation | mm | 0,005 | |

| Tool magazine | Magazine | 2x24 | |

| Max. tool length | mm | 350 | |

| Tool diameter | mm | Ø140 | |

| Tool change time | s | 2,5-3 | |

| Workpiece | Dimensions | mm | 300x300x400 |

| Planet size | mm | Ø225 | |

| Cooling | Through the spindle | l/min | 50/120 |

| Controls | Siemens SINUMERIK ONE/FANUC |

||

| Machine data | Length | mm | 4.500 |

| Width | mm | 2.000 | |

| Height | mm | 2.850 | |

| Weight | kg | 18.500 | |

| Technical details may vary depending on customer specifications. | |||

MACHINE CONCEPT

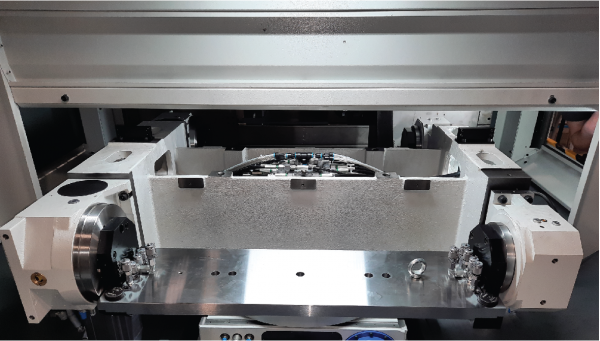

- 5-axis version with A-axis and planet

- 4-axis version with A-axis

- 5-axis version with double A-axis and rotary table with B-axis and planet

- 4-axis version with double A-axis and rotary table with B-axis

WORKPIECES

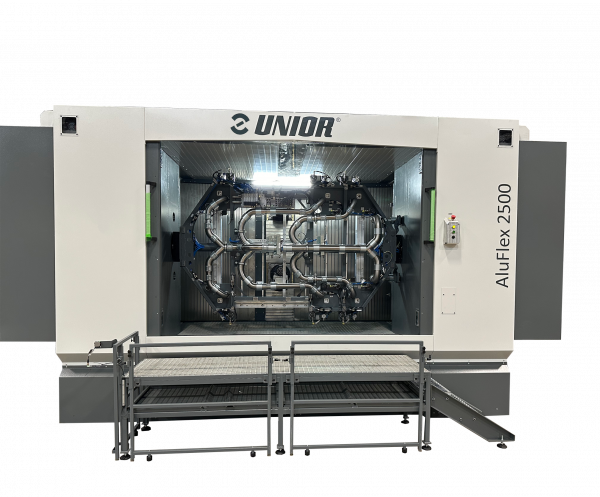

ALUFLEX 1500/2000/2500

The 4-axis machining center enables optimal machining of thin-walled steel and thick-walled aluminium profi les. The rigid machine structure ensures high machining speeds and accuracy. The 2500 model enables the machining of welded battery frames.

ADVANTAGES

- Dry machining/upgrade to MQL or flood cooling

- Flexible machining of aluminium or thin-walled steel pro files

- Machining of workpieces up to a length of 2500 mm and a width of 1500 mm

- Change of clamping device enables fast changeover to a new workpiece. Possibility of changing the clamping fixture via robot

- Pneumatic clamping system with possible upgrade to a hydraulic system

- Machining possibility - two di erent workpieces

- Option of a 5-Axis version

TECHNICAL DATA

| Working area | X-Axis | mm | 2.000 |

| Y-Axis | mm | 800 | |

| Z-Axis | mm | 630 | |

| Working Spindle | Max. RPM | U/min | 18.000 |

| Max. Power | kW | 10 | |

| Tool interface | HSK | 63 | |

| Max. torque | Nm | 45 | |

| Acceleration | X-Axis | m/s² | 8 |

| Y-Axis | m/s² | 8 | |

| Z-Axis | m/s² | 10 | |

| Accuracy | Position tolerance | mm | <0,01 |

| Position deviation | mm | 0,005 | |

| Tool Magazine | Magazine | 28 | |

| Max. tool length | mm | 350 | |

| Tool diameter | mm | Ø100 | |

| Workpieces | Battery frame | mm | 200x1500x2500 |

| Aluminum profile | mm | 300x300x2000 | |

| Cooling | Dry processing | Possible upgrade to MQL/flood cooling | |

| Controls | Siemens SINUMERIK ONE/FANUC |

||

| Machine data | Length | mm | 7.700 |

| Width | mm | 3.700 | |

| Height | mm | 3.000 | |

| Weight | kg | 24.000 | |

| Technical details may vary depending on customer specifications. | |||

MACHINE CONCEPT

A solid welded construction lled with mineral concrete, which ensures optimal vibration damping

Horizontal design for optimal chip evacuation

Modular design:

- one station, one spindle

- two stations, one spindle/station

- one station, two spindles

- two stations, two spindles/stations

Possibility of clamping several smaller workpieces to increase productivity

WORKPIECES

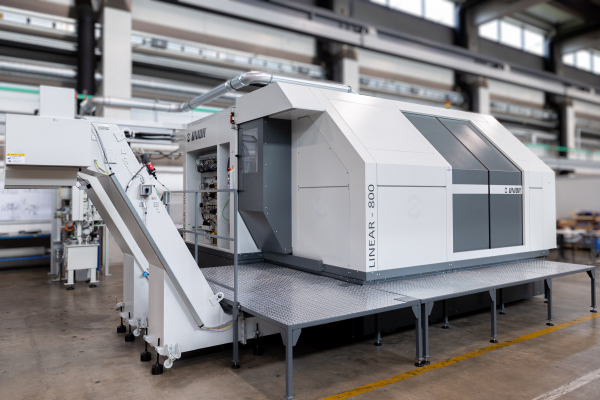

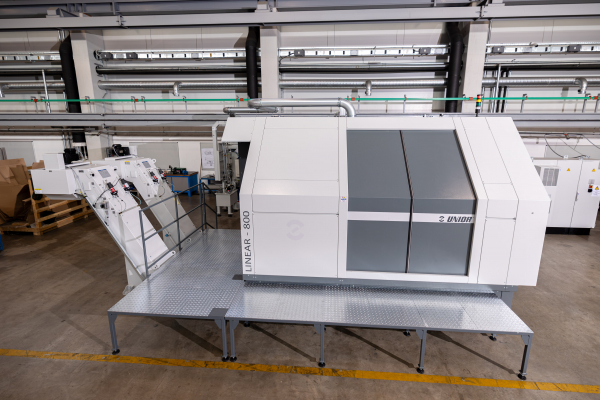

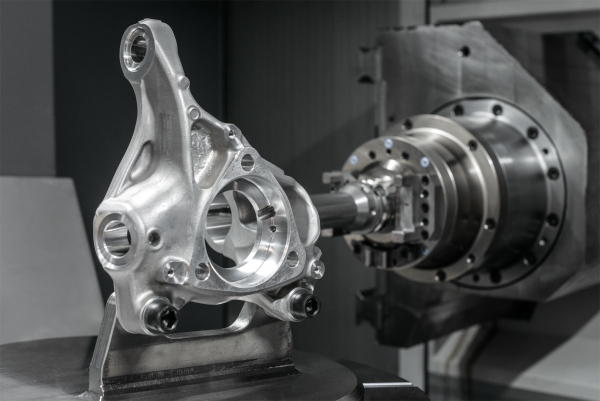

5-AXIS MACHINING CENTER LINEAR 800L

LINEAR 800 L is a high-tech processing centre for large-scale production. The practically oriented and improved modular design with rigid components ensures high stability, precision, productivity and operability.

ADVANTAGES

- Designed for larger workpieces

- Linear drives for high speed

- 5-axis machining

- Automatic hydraulic clamping

TECHNICAL DATA

| Workspace area | X-Axis | mm | 1.700 |

| Y-Axis | mm | 1.000 | |

| Z-Axis | mm | 700 | |

| Working Spindle | Max. RPM | U/min | 20.000 |

| Max. power | kW | 28 | |

| Clamp type | HSK | 80 | |

| Acceleration | X-Axis | m/s² | 4 |

| Y-Axis | m/s² | 4 | |

| Z-Axis | m/s² | 6 | |

| Precision | Position tolerance | mm | <0,01 |

| Position deviation | mm | 0,005 | |

| Tool magazine | Magazine | 20/72/120 | |

| Max. tool length. | mm | 350 | |

| Workpiece | Dimensions | mm | 1.200x1.100x500 |

| Cooling | Through the spindle | l/min | 60 |

| Controls | Siemens SINUMERIK ONE |

||

| Machine data | Length | mm | 4.500 |

| Width | mm | 4.500 | |

| Height | mm | 3.580 | |

| Weight | kg | 17.000 | |

| Technical data may vary due to customers specifications. | |||

MACHINE CONCEPT

- The zero-point clamping system allows flexibility and automatic change of clamping devices. The system ensures high clamping device positioning repeatability

- Linear drives are used due to the long strokes of the X and Z axes

- The system allows high dynamics over long distances and under high loads

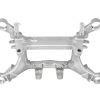

WORKPIECES

UNIVERSAL 2-SPINDLE 5-AXIS MACHINING CENTER TANDEM 700L

TANDEM 700 L is a high-tech processing center for high productivity and large production. Practically oriented and enhanced modular design with rigid components, guarantee a high stability, constant precision, high productivity and high operability.

ADVANTAGES

- High flexibility

- Processing of mirror workpieces (L&R)

- Processing of high precision workpieces

- NC adjustments of each processing axis

TECHNICAL DATA

| Workspace area (2x) | X-Axis | mm | 800 |

| Y-Axis | mm | 800 | |

| Z-Axis | mm | 700 | |

| Working Spindle (2x) | Max. RPM | U/min | 20.000 |

| Max. power | kW | 28 | |

| Tool interface | HSK | 63/80 | |

| Acceleration (2x) | X-Axis | m/s² | 5 |

| Y-Axis | m/s² | 5 | |

| Z-Axis | m/s² | 10 | |

| Accuracy | Position tolerance | mm | <0,01 |

| Position deviation | mm | 0,005 | |

| Tool magazine | Magazine | 72/120 | |

| Max. tool length | mm | 420 | |

| Workpiece | Dimensions | mm | 500x500x600 |

| Coolant | Through the spindle | l/min | 60 |

| Controls | Siemens SINUMERIK ONE |

||

| Machine data | Length | mm | 5.300 |

| Width | mm | 5.100 | |

| Height | mm | 3.700 | |

| Weight | kg | 32.000 | |

| Technical data may vary due to customers specifications. | |||

MACHINE CONCEPT

The Tandem 5-axis double spindle machining center with two independent X, Y and Z axes and 1, 2 or 4 planetary tables that enable universal machining of identical, mirror and in some cases di fferent workpieces. With its robust construction, the 5-axis Tandem machining centre with two spindles can achieve high productivity and high machining quality. The Tandem series is the ideal machining centre for high-precision machining of workpieces in large batches.

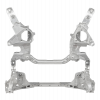

WORKPIECES